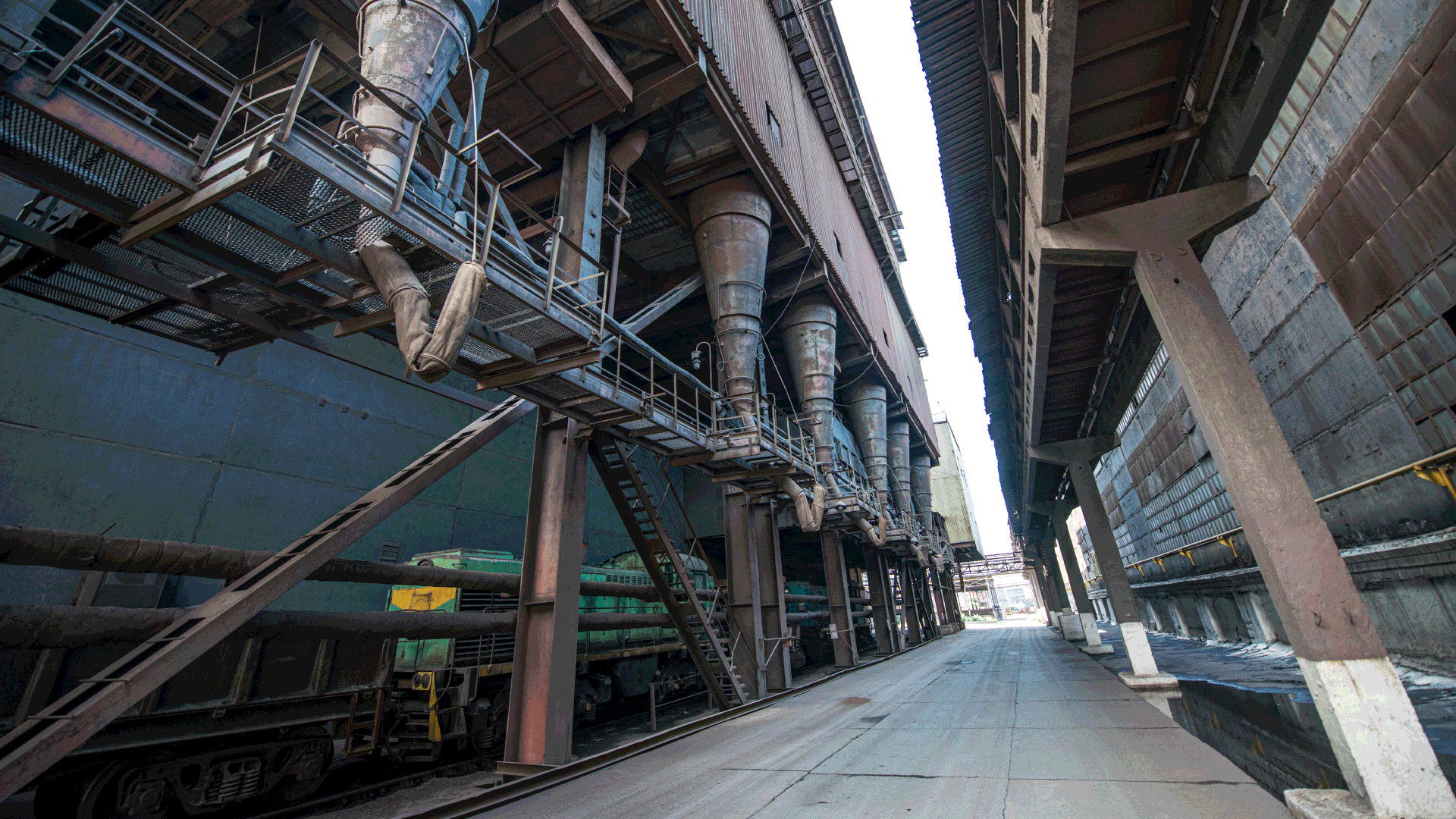

Metallurgy

From the most remote corners of the Earth comes the fuel that makes modern life possible.

MLG Metallurgy Services – Technical Overview

MLG’s Metallurgical & Process Engineering division provides world-class expertise across the full cycle of mineral processing development. From laboratory testwork and pilot trials to flowsheet design and cost analysis, our approach is rigorous, data-driven, and tailored to the unique characteristics of each orebody. We specialize in flotation and hydrometallurgy process optimization, ensuring maximum metal recovery and sustainable operation. Our engineers and metallurgists leverage advanced modeling tools and international best practices to deliver scalable, cost-effective process solutions for a broad range of commodities. Every project is supported with precise planning, real-time QA/QC, and transparent CAPEX/OPEX forecasts to ensure technical and financial success.

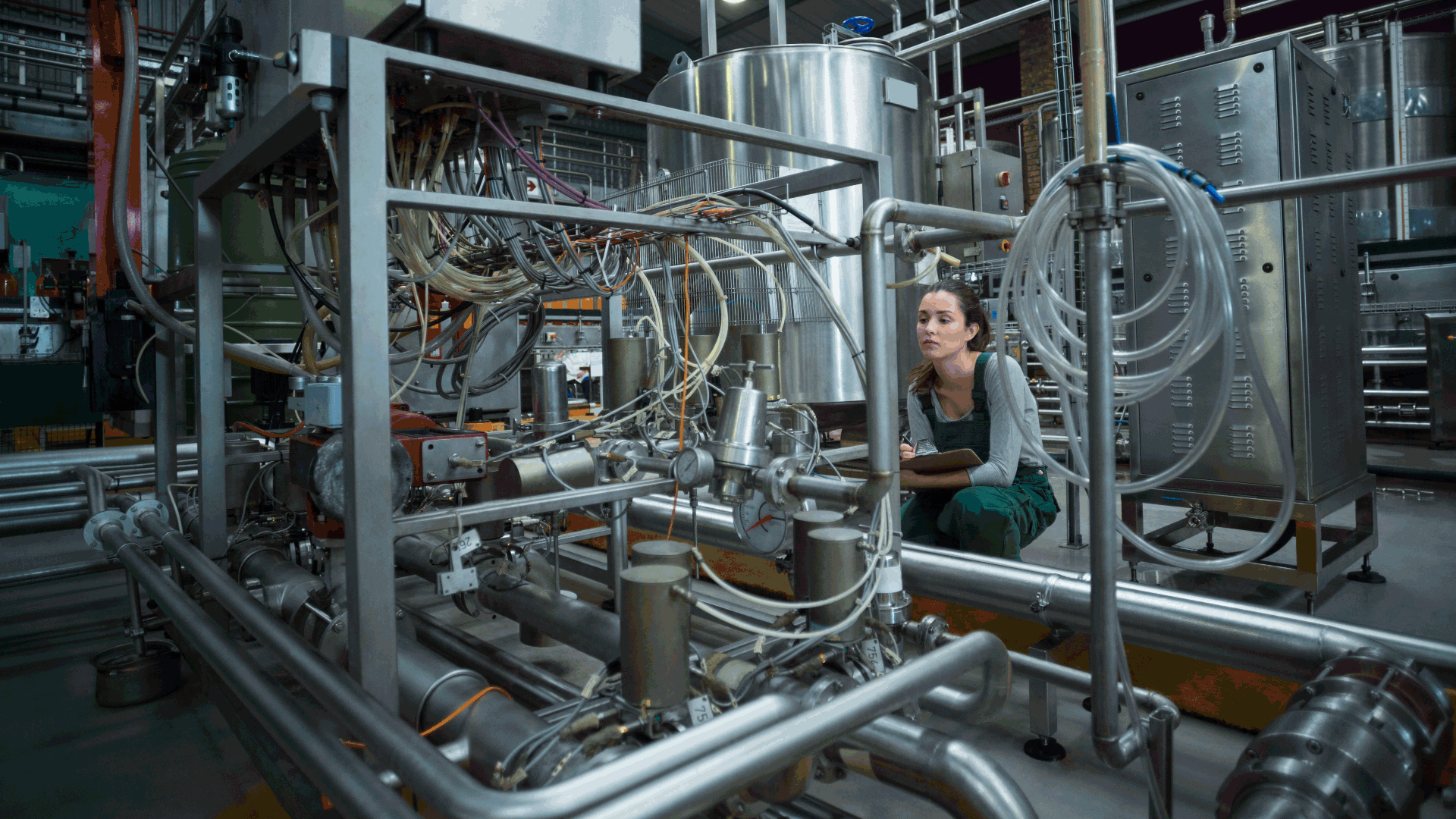

Metallurgical tests

MLG provides advanced metallurgical testing services essential for developing and validating efficient ore processing flowsheets. The testing program begins with the selection and preparation of representative ore composites, typically referred to as the “Master Blend,” sourced from drill core samples across the entire orebody. These samples reflect the variability and long-term feed characteristics of the deposit. We conduct a full suite of tests including metallographic, mineralogical, physico-mechanical, and physico-chemical analyses, supported by state-of-the-art mineral mapping tools such as QEMSCAN and MLA. Characterization tests (crushing, grinding, gravity separation, flotation, cyanidation, etc.) are executed at laboratory scale, followed by semi-industrial scale tests (2 t/h) to validate process efficiency. Each step is governed by strict QA/QC protocols to ensure data reliability and scalability.

Flotation

MLG offers comprehensive flotation testing and circuit optimization services tailored to the mineralogy of the ore. Bench-scale flotation tests and locked-cycle flotation tests are designed to identify optimal reagent schemes, frother and collector combinations, and pH conditions. Our team also performs column flotation and pilot-scale tests to simulate real-world process conditions. Particular attention is paid to maximizing recovery rates while controlling concentrate grade and minimizing reagent consumption. The flotation test work feeds directly into the development of flotation circuits, with mass balance modeling and performance forecasting incorporated into design parameters for industrial implementation.

Hydrometalurgy

In projects where leaching is more appropriate than flotation, MLG designs and executes hydrometallurgical testing including heap leaching, column leaching, and agitation leach tests. Cyanide leaching, especially for gold and silver ores, is optimized for maximum metal recovery while adhering to environmental safety standards. When required, we conduct detoxification tests to evaluate cyanide destruction methods such as SO₂/air, peroxide, or Caro’s acid processes. Our hydrometallurgical solutions are tailored to the ore’s chemistry and the project’s environmental constraints, ensuring regulatory compliance and economic feasibility.

Process design

Following metallurgical validation, MLG proceeds with detailed process design using industry-standard tools. This includes the development of conceptual and detailed Process Flow Diagrams (PFDs), Piping and Instrumentation Diagrams (P&IDs), and comprehensive mass and water balances. We define critical process parameters and operating conditions, specify process control strategies, and generate technical datasheets for each unit operation. Equipment sizing is supported by engineering calculations, considering throughput, ore characteristics, and process kinetics. These deliverables feed into a robust design basis that underpins feasibility studies and engineering development.

Planning

MLG manages the metallurgical test work and design phases with integrated planning strategies. This includes establishing test schedules, deliverable milestones, and data validation checkpoints aligned with project timelines. Results from each phase are compiled into technical reports that guide further engineering and project development. Optimization loops are integrated early to refine flowsheets and anticipate scale-up issues. Planning also involves coordination with other disciplines (e.g., mining, infrastructure, environment) to ensure a seamless interface across all project components.

Infrastructure and costs

MLG provides detailed capital (CAPEX) and operating (OPEX) cost estimates based on metallurgical design outcomes. This includes equipment procurement lists, layout plans, piping and instrumentation estimates, and utility demand projections (e.g., power, water, reagents). Operating costs are derived from reagent consumption, wear rates, labor estimates, and energy profiles validated by pilot-scale testing. All cost models are structured to support trade-off studies and investment decision-making, with cost-benefit analyses integrated into the final process selection.